Building Out Of the Box

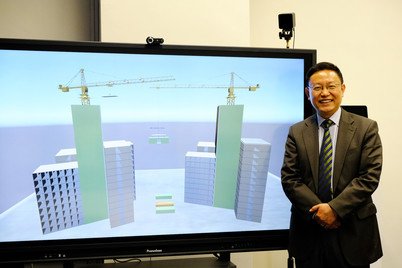

Modular Integrated Construction (MiC) is a solution for buildings of higher quality, affordability, productivity and sustainability in Hong Kong. Dr Wei Pan is leading impact-driven MiC research, of which knowledge exchange is crucial to shape future building.

The need for affordable housing is acute in Hong Kong, which has the highest population density in the world and where prices for apartments are also the highest in the world, placing the dream of home ownership beyond the reach of most people. Fixing Hong Kong’s housing shortage is made more complex by the falling numbers of construction workers and the industry’s ageing labour force, and these problems are compounded by the high cost of construction in Hong Kong, second only to New York.

But what if the actual construction of apartments could take place offsite, in places where labour is plentiful and costs are lower, and the ready-made apartments could simply be assembled with the load-bearing core of the building on site? That is the out-of-the-box thinking which has led to the development of Modular Integrated Construction (MiC).

The advantages of MiC have already been recognised in other places and will be particularly beneficial in high-density Hong Kong. Several up-to-20-storey buildings are currently being built in Hong Kong using MiC. “The idea is to minimise activities on site,” explained Dr Wei Pan, Associate Professor of the Department of Civil Engineering and Executive Director of the Centre for Innovation in Construction and Infrastructure Development, who described his work as impact-driven research that directly impacts government policy and advises construction.

With MiC, construction and labour is largely removed from the site to factories located in the Greater Bay Area, the Yangtze River Delta and different parts of Southeast Asia. These locations share the advantages of increased labour availability, bigger spaces for factories, and lower labour and building costs.

In factories, apartments are built in modular form. Not only are the plumbing and electricals pre-installed, but also flooring, painting, and furniture such as beds and wardrobes and even ceramic fittings are prefinished. Staircases and lifts can also be integrated into the modules, so can façades and claddings. The modules are then transported to the building site in Hong Kong where excavation, piling and on-site works take place. The end result is apartments that are much more affordable than those built on site.

There are other important benefits too. Using MiC cuts construction time dramatically, with the timeline for building a 20-storey apartment block reduced by around one year. Construction waste is massively reduced and the construction process results in less noise, dust and space disturbance to city dwellers.

Health and safety benefits from safer working conditions in the factories and a shorter construction process and fatal accidents have fallen by over half. In a typical bathroom or kitchen, about 25 construction trades work together in the small space, with overlapping tasks and under time pressure. By shifting works to factories, workers can carry out different tasks simultaneously in safer and more spacious conditions.

Dr Wei Pan of the Department of Civil Engineering received the Faculty Knowledge Exchange Award 2019 of the Faculty of Engineering for the project ‘Modular Integrated Construction (MiC) for Buildings of Higher Quality, Productivity and Sustainability in Hong Kong’.

![Modular Integrated Construction (MiC) design, transport and installation [photo courtesy of China International Marine Containers (Group) Co., Ltd., Dragages Singapore Ltd., Tide Construction Ltd. and Atlantic Modular System Ltd. (from left)]](/f/story/1059/402p275/Screenshot%202019-10-24%20at%205.39.25%20PM.png)